Even new oil can be contaminated and not supplied to the cleanliness standards required for a modern hydraulic system.The most common standard used to rate cleanliness areNAS 1638: 1964 and ISO 4406:199.

A. NATIONAL AEROSPACE STANDARD – NAS 1638

The NAS system was originally developed in 1964 to define contamination classes for the contamination contained within aircraft components. The application of this standard was extended to industrial hydraulic systems simply because nothing else existed at the time

The coding system defines the maximum numbers permitted of 100mL volume at various size intervals (differential counts) rather than using cumulative counts as in ISO 4406.

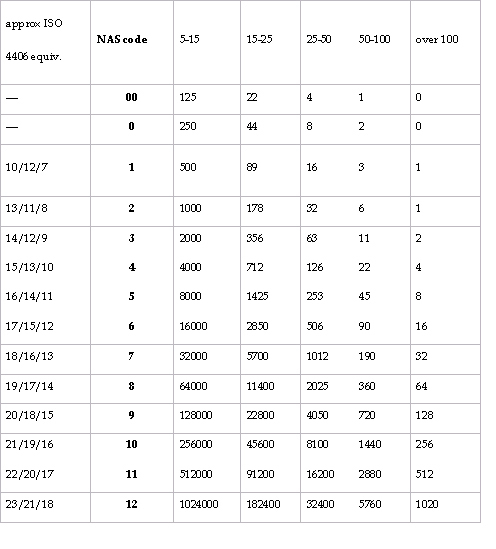

CONTAMINATION LEVEL CLASSES according to NAS 1638 (January 1964)

The contamination classes are defined by a number (from 00 to 12) which indicates the maximum number of particles per 100 ml, counted on a differential basis, in a given size bracket.

MAXIMUM CONTAMINATION LIMITS (PER 100 ml)

size range in microns

B. INTERNATIONAL STANDARD ISO 4406 : 1999

Hydraulic Fluid Power – Fluids – Method For Coding The Level Of Contamination by solid particles

1. Scope

This International Standard specifies the code to be used in defining the quantity of solid particles in the fluid used in a given hydraulic fluid power system.

2. Normative References

ISO 4407:1991, Hydraulic fluid power – Fluid contamination – Determination of particulate contamination by the counting method using a microscope.

ISO 11171:1999, Hydraulic fluid power – Calibration of automatic particle counters for liquids.

ISO 11500:1997. Hydraulic fluid power – Determination of particulate contamination by automatic counting using the light extinction principle.

3. Code Definition

3.1. General

The Purpose of this code is to simplify the reporting the particle count data by converting the numbers of particles into broad classes or codes, where an increase in one code is generally a doubling of the contamination level.

The original code in accordance with ISO 4406:1987 stated the reporting at two size, ? 5 µm and ? 15 µm, but the sizes in this revision have been changed to account for the use of a different calibration standard for optical automatic particle counters. The reported sizes are ? 4 µm[c], ? 6 µm[c] and ? 14 µm[c], the last two of these being equivalent to the 5 µm and 15 µm particle sizes obtained using the ISO 4402:1991 method of calibrating automatic particle counters. ISO 4402:1991 has been replaced by ISO 11171:1999. Throughout this International Standard, the use of µm[c] means that particle size measurements are carried out using an automatic particle counter which has been calibrated in accordance with ISO 11171.

Measurement of particles using an optical microscope as specified in ISO 4407:1991 establishes the size of a particle as being equal to its longest dimension, where as an automatic particle counter derives the size of an equivalent particle form its cross-sectional area, a value different in most cases from that determined using a microscope. The particle sizes to be reported for measurement by microscope, ? 5 µm and ? 15 µm, are unchanged from those specified in ISO 4406:1987.

CAUTION – Particle Counts are affected by a variety of factors. These factors include procurement of sample, particle counting accuracy, and the sample container, where used, and its cleanliness. Proper care should be taken during sample procurement to ensure that the sample obtained is representative of the fluid circulation in the system.

3.2. Basis of Code

The code for contamination levels using automatic particle counters comprises three scale numbers, which permit the differentiation of the dimension and the distribution of the particles as follows :

— the first scale number represent the number of particle equal to or larger than 4 µm[c] per milliliter of fluid;

— the second scale number represent the number of particle equal to or larger than 6 µm[c] per milliliter of fluid;

— the third scale number represent the number of particle equal to or larger than 14 µm[c] per milliliter of fluid;

The code for microscope counting comprises two scale numbers using 5 µm and 15 µm.

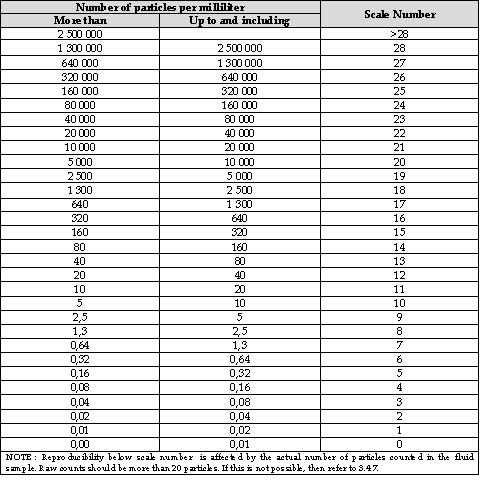

3.3. Allocation of Scale Numbers

3.3.1. The Scale numbers are allocated according to the number of particles counted per milliliter of the fluid sample (see table 1).

3.3.2. A step ratio of generally two, as given between the upper and lower limits for the numbers within a reasonable limit and to ensure that each step is meaningful.

3.4. Determination of code using automatic particle counter analysis

3.4.1. Counting shall be undertaken in accordance with ISO 11500 or another recognized method, using an automatic particle counter calibrated to ISO 11171.

3.4.2. A scale number shall be allocated to the number of particles equal to or larger than 4 µm[c].

3.4.3. A second scale number shall be allocated to the number of particles equal to or larger than 6 µm[c].

3.4.4. A third scale number shall be allocated to the number of particles equal to or larger than 14 µm[c].

3.4.5. The three numbers shall be written one after the other and separated by oblique strokes (slashes).

EXAMPLE :

A code of 22/18/13 signifies that there are more than 20.000 and up to and including 40000 particles equal to or larger than 4 µm[c], more than 1300 and up to and including 2500 particles equal to or larger than 6 µm[c] and more than 40 and up to and including 80 particles equal to or larger than 14 µm[c] in 1ml of a given fluid sample.

3.4.6. When applicable, include either a “*” (too numerous to count) or a “__” (no requirement to count) notation when reporting the scale number.

EXAMPLE 1

*/19/14 means that this sample has too many particles equal to or larger than 4 µm[c] to count.

EXAMPLE 2

—/19/14 means that there was no requirement to count particles equal to r larger than 4 µm[c].

Table 1 — Allocation of scale numbers

3.4.7. When the raw data in one of the size ranges results in a particle count of fewer than 20 particles, the scale number for that size range shall be labeled with the symbol ?.

EXAMPLE

A code of 14/12/? 7 signifies that there are more than 80 and up to and including 160 particles equal to or larger than 4 µm[c] per milliliter and more than 20 and up to and including 40 particles equal to or larger than 6 µm[c] per milliliter. The third part of the code, ? 7, indicates that there are more than 0,64 and up to and including 1,3 particles equal to or larger than 14 µm[c] per milliliter, but less than 20 particles were counted, which lowers statistical confidence. Because of this lower confidence, the 14 µm[c] part of the code could actually be higher than 7, indicating a particle count more than 1,3 particles per milliliter.

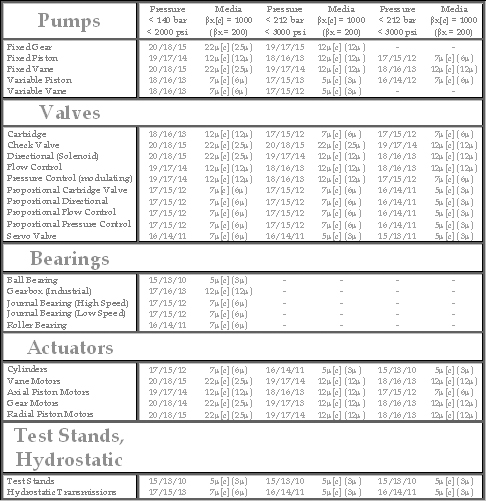

C. SELECTING TARGET ISO CLEANLINESS CODES

When setting target ISO fluid cleanliness codes for hydraulic and lubrication systems it is important keep in mind the objectives to be achieved. Maximizing equipment reliability and safety, minimizing repair and replacement costs, extending useful fluid life, satisfying warranty requirements, and minimizing production down-time are attainable goals. Once a target ISO cleanliness code is set following a progression of steps to achieve that target, monitor it, and maintain it justifiable rewards will be yours.

Set the Target

The first step in identifying a target ISO code for a system is to identify the most sensitive on an individual system, or the most sensitive component supplied by a central reservoir. If a central reservoir supplies several systems the overall cleanliness must be maintained, or the most sensitive component must be protected by filtration that cleans the fluid to the target before reaching that component.

Other Considerations

Table 1 recommends conservative target ISO cleanliness codes based on a several component manufacturers guidelines and extensive field studies for standard industrial operating conditions in systems using petroleum based fluids. If a non-petroleum based fluid is used (i.e. water glycol) the target ISO code should be set one value lower for each size (4µ[c]/6µ[c]/14µ[c]). If a combination of the following conditions exists in the system the target ISO code should also be set one value lower:

Component is critical to safety or overall system reliability.

Frequent cold start.

Excessive shock or vibration.

Other severe operation conditions.

Recommended* Target ISO Cleanliness Codes and media selection for systems using petroleum based fluids per ISO4406:1999 for particle sizes 4 µ[c] / 6 µ[c] / 14 µ[c]

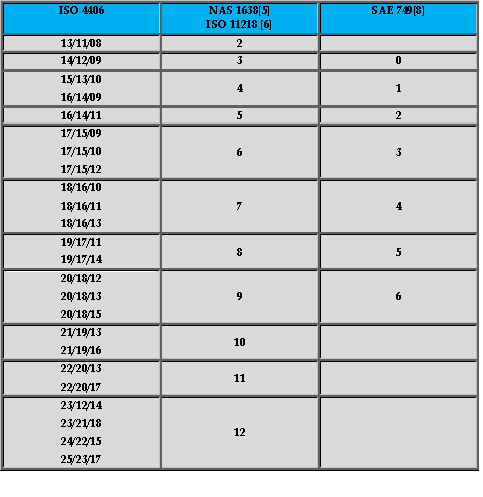

D. COMPARISON OF CLEANLINESS STANDARD

Although the ISO 4406 standard is being used extensively within the hydraulics industry other standards are occasionally required and a comparison may be requested. The following table gives a very general comparison but often no direct comparison is possible due to the different classes and sizes involved.

*All section headings indicated with [] are reproduced by kind permission of British Fluid Power Association from BFPA/P5 1999